Technology

AUTOGAS SYSTEMS

Because the technology around fuel delivery of the base petrol engines has developed over the years that Autogas has been used, there are several types of systems which have evolved. The three most popular Autogas system types are:

Venturi systems

Also known as converter and mixer or vacuum type systems. These are mechanically the simplest and can be made to work without any electronics. They consist of the three basic elements: fuel tank, converter (vaporiser/regulator) and mixer. While no longer conforming to the newest emissions regulations they can still be used to convert older carburetted vehicles or machinery.

Vapour sequential injection systems

Inject the fuel in the gaseous phase but align the gas injections to what the original electronic gasoline controls of the car command. These fully sequential systems achieve the latest emissions stages.

Liquid injection systems

Exactly replicate gasoline systems and inject the fuel in the liquid phase without prior vaporisation. This enables more precise metering of the fuel and an injection timed to the opening of the intake valves.

GENERATIONS OF AUTOGAS SYSTEMS

Because the technology around fuel delivery of the base petrol engines has developed over the years that Autogas has been used, there are several types of systems which have evolved. The three most popular Autogas system types are:

6th Generation

Liquid phase direct injection (LPdi): Currently the most advanced system, LPdi, much like gasoline direct injection, utilises a high-pressure pump and injectors to inject LPG in liquid phase directly into the combustion chamber. The fuel vaporises instantly, increasing the anti-knock behaviour of the fuel, unlocking the true potential of the engine design while at the same time drastically reducing emissions.

5th Generation

Liquid phase injection (LPI): This type of system no longer needs a converter, and instead injects the liquid fuel in a liquid state in much the same manner as a gasoline-injection system. Because the fuel vaporises in the intake, the air around it is cooled substantially; this increases the density of the intake air and can potentially lead to substantial increases in engine power output. LPI systems achieve better fuel economy and power as well as lower emission than vapour systems.

4th Generation

Vapour phase injection: Also known as a gaseous phase sequential injection, this system still relies on a converter to vaporise the gas like the old systems, but the injection takes place via a series of electrically controlled injectors. This allows for more accurate metering of fuel to the engine than was possible with previous generations. As a result fuel economy, power and emissions are much improved. The injector opening times are controlled by the original gasoline control unit, which the Autogas electronics then translate into the correct values taking into account the different fuel behaviour and injector construction. It is still the most widely available type and most often used for retrofits.

3rd Generation

Continuous flow injection: This system corrected deficiencies found in the first systems. It combined electronic controls found in second generation systems, which adjusted the mixture with an electronically controlled valve according to lambda sensor inputs, and injected the fuel directly into the manifold. This is often referred to as a semi-sequential system.

2nd Generation

Electronically controlled venturi: Basically the same as a 1st-generation system except for the electronic adjustment of the air-fuel ratio. This was achieved through a variable valve actuated by a stepper motor between converter and mixer. This valve is set by the lambda control module which reads out an oxygen sensor (lambda sensor) and attempts to maintain a constant mixture.

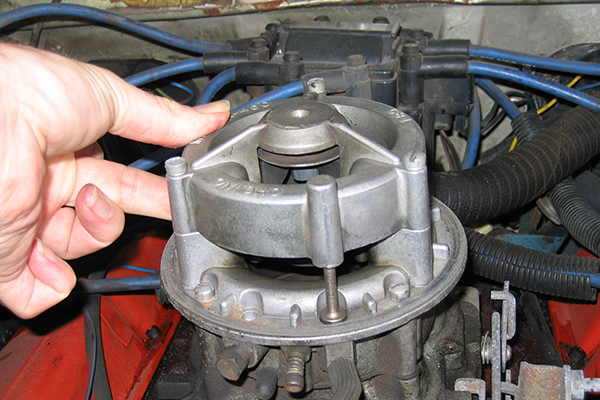

1st Generation

Converter-and-mixer: Also known as a venturi or vacuum system, this is the oldest system, having been used since its inception the 1930s, and is still in use today in some parts of the world. Like almost all vapour phase systems, it uses a converter to vaporise the liquid fuel coming from the tank, which is then fed to the mixer in the intake at a regulated (lower) pressure. There the airflow through the mixer automatically meters the flow of gas roughly achieving an approximate air-fuel ratio.